При транспортировке и хранении криогенных сред, таких как сжиженный природный газ (СПГ), жидкий азот, жидкий кислород и жидкий водород, надежность и ремонтопригодность клапанов имеют решающее значение. Криогенные поворотные дисковые затворы не только способны безотказно работать при экстремально низких температурах, но и спроектированы с учётом простоты обслуживания, что позволяет пользователям значительно экономить время и средства на техническое обслуживание.

Криогенный дисковый затвор — это тип клапана, специально разработанный для трубопроводных систем криогенных сред, в основном используемый для открытия, закрытия и регулирования потока жидкости. В отличие от стандартных дисковых затворов, он изготовлен из криогенно-стойких материалов и имеет специальную конструкцию, что позволяет ему надёжно работать в экстремальных условиях, например, при температуре -196 ℃, сохраняя при этом отличную герметичность и плавность работы.

● Надежная герметизация и безопасность

Специальная конструкция манжетного уплотнения обеспечивает клапан остается герметично закрытым в криогенных условиях.

Противовыбросовая конструкция штока повышает безопасность эксплуатации.

● Особенность: простота обслуживания

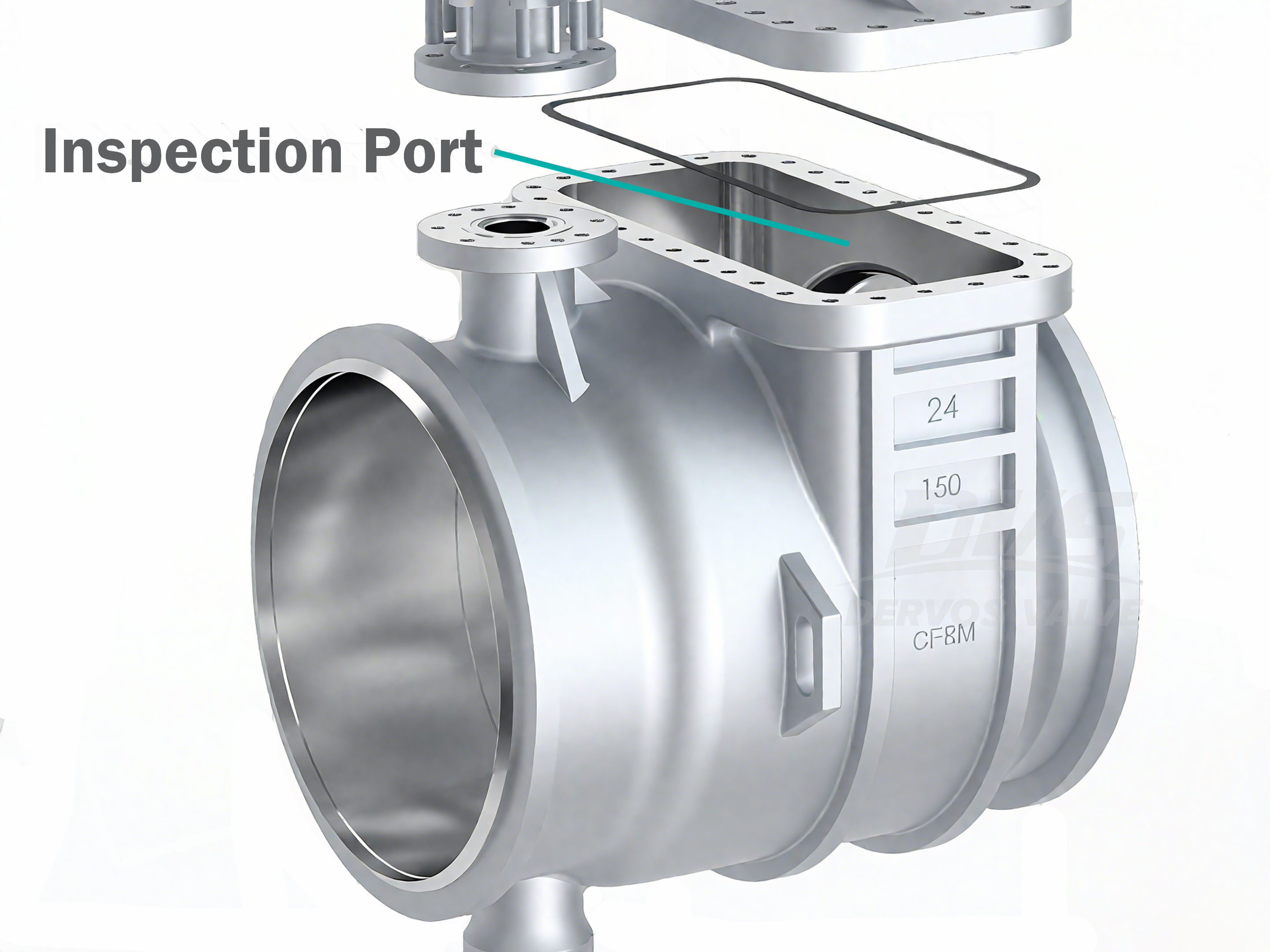

Встроенный инспекционный порт: одно из наиболее заметных преимуществ криогенных дисковых затворов. Без разборки всего трубопровода уплотнения, сальники и другие критически важные компоненты можно осмотреть и заменить непосредственно через инспекционный порт.

● Просторная полость

Корпус клапана спроектирован с большим внутренним пространством, что облегчает проведение технического обслуживания с помощью инструментов и операторов, что значительно сокращает время простоя.

● Удлиненная конструкция штока

Шток удлинен для того, чтобы область уплотнения всегда работала при температуре окружающей среды, предотвращая выход из строя уплотнения из-за криогенных условий.

● Модульное уплотнение сальника

Гибкость сборки и разборки обеспечивает легкую замену, повышая эффективность обслуживания.

● Криогенная стойкость и длительный срок службы

Уплотнительная поверхность седла клапана полностью закалена и отполирована с использованием специализированных процессов, что позволяет достичь точности уплотнения Ra0,2, что обеспечивает более длительный срок службы.

● Корпус из аустенитной нержавеющей стали

Корпус клапана изготовлен из двухслойной аустенитной нержавеющей стали, обеспечивающей как коррозионную стойкость, так и превосходную ударную вязкость при низких температурах.

● Защита от конденсата и стабильная работа

Поддоны для капель и опоры дренажных канавок разработаны для эффективного предотвращения попадания конденсата в зону уплотнения, что снижает частоту технического обслуживания.

● Гибкая адаптивность

Соединительный фланец спроектирован в соответствии с международными стандартами, что позволяет при необходимости устанавливать ручные, пневматические или электрические приводы.

Быстрое обслуживание: смотровое отверстие в сочетании с просторной конструкцией полости упрощает обслуживание и сокращает время простоя.

Безопасная эксплуатация: Противовыбросовый шток и противоконденсатная конструкция обеспечивают долговременную стабильную работу.

Долговечность: высокопрочные криогенные материалы и закаленные уплотнительные поверхности продлевают срок службы.

Широкое применение: подходит для различных криогенных сред, включая СПГ, жидкий азот, жидкий кислород, нефтехимическую и энергетическую промышленность.

Системы хранения и транспортировки СПГ

Производство и транспортировка жидкого азота, жидкого кислорода и жидкого водорода

Криогенные процессы в нефтехимической и энергетической промышленности

По сравнению со стандартными дисковыми затворами, преимущества криогенных дисковых затворов заключаются не только в их способности выдерживать низкие температуры, но и в простоте обслуживания. Благодаря встроенному смотровому отверстию, оптимизированной конструкции и просторной зоне обслуживания пользователи могут быстро выполнять обслуживание, сокращать время простоя и повышать общую эффективность эксплуатации. Это делает криогенные дисковые затворы более экономичным и надежным решением для различных криогенных применений.

В1: Какова основная особенность криогенных поворотных заслонок?

А1: По сравнению со стандартными дисковыми затворами, основное преимущество криогенных дисковых затворов заключается в простоте обслуживания. Благодаря наличию смотрового окна и просторной полости, обслуживание можно проводить без демонтажа трубопровода, что значительно сокращает время простоя.

В2: Почему криогенные поворотные заслонки требуют специальной конструкции?

А2: Криогенные среды, такие как СПГ или жидкий азот, могут достигать температуры -196 ℃. Стандартные клапаны в таких условиях склонны к хрупкости и потере герметичности. Криогенные поворотные дисковые затворы изготавливаются из специальных материалов и конструкций, обеспечивающих безопасную и надёжную работу даже при экстремально низких температурах.

В3: Каков типичный срок службы криогенный дроссельный клапан ?

А3: Благодаря использованию двухклассной аустенитной нержавеющей стали и полностью закаленным полированным уплотнительным поверхностям криогенные дисковые затворы, как правило, имеют более длительный срок службы, чем стандартные дисковые затворы. Точный срок службы зависит от условий эксплуатации и практики технического обслуживания.

В4: Требуются ли для обслуживания криогенных дроссельных клапанов специальные инструменты?

А4 : Не требуется сложных инструментов. Проверка и замена компонентов просты и могут выполняться штатным специалистом по техническому обслуживанию, что значительно снижает затраты на обслуживание.

В5: В каких отраслях промышленности могут применяться криогенные поворотные заслонки?

А5: К типичным областям применения относятся резервуары для хранения СПГ и транспортные трубопроводы, установки для производства жидкого азота, жидкого кислорода и жидкого водорода, а также криогенные процессы в нефтехимической и энергетической промышленности.